DeMiner

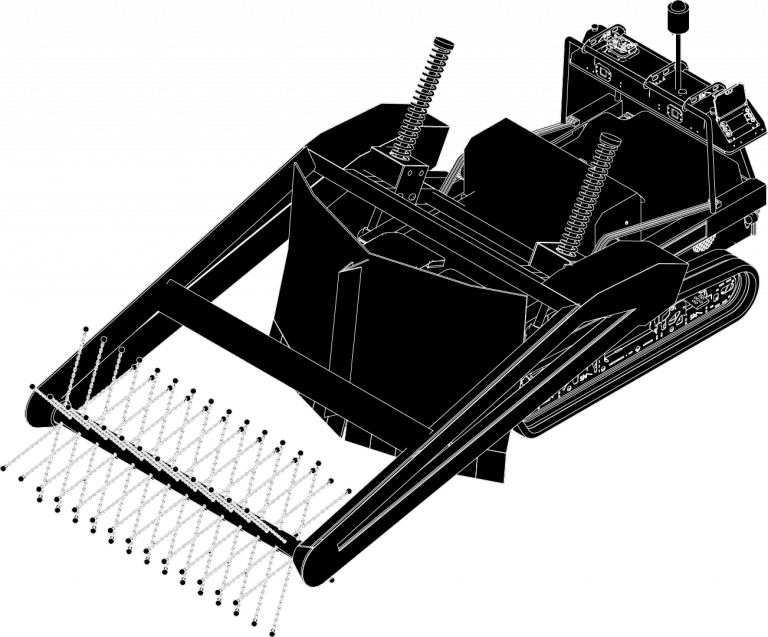

Autonomous Mechanical Flail Demining System

MAIN FEATURES

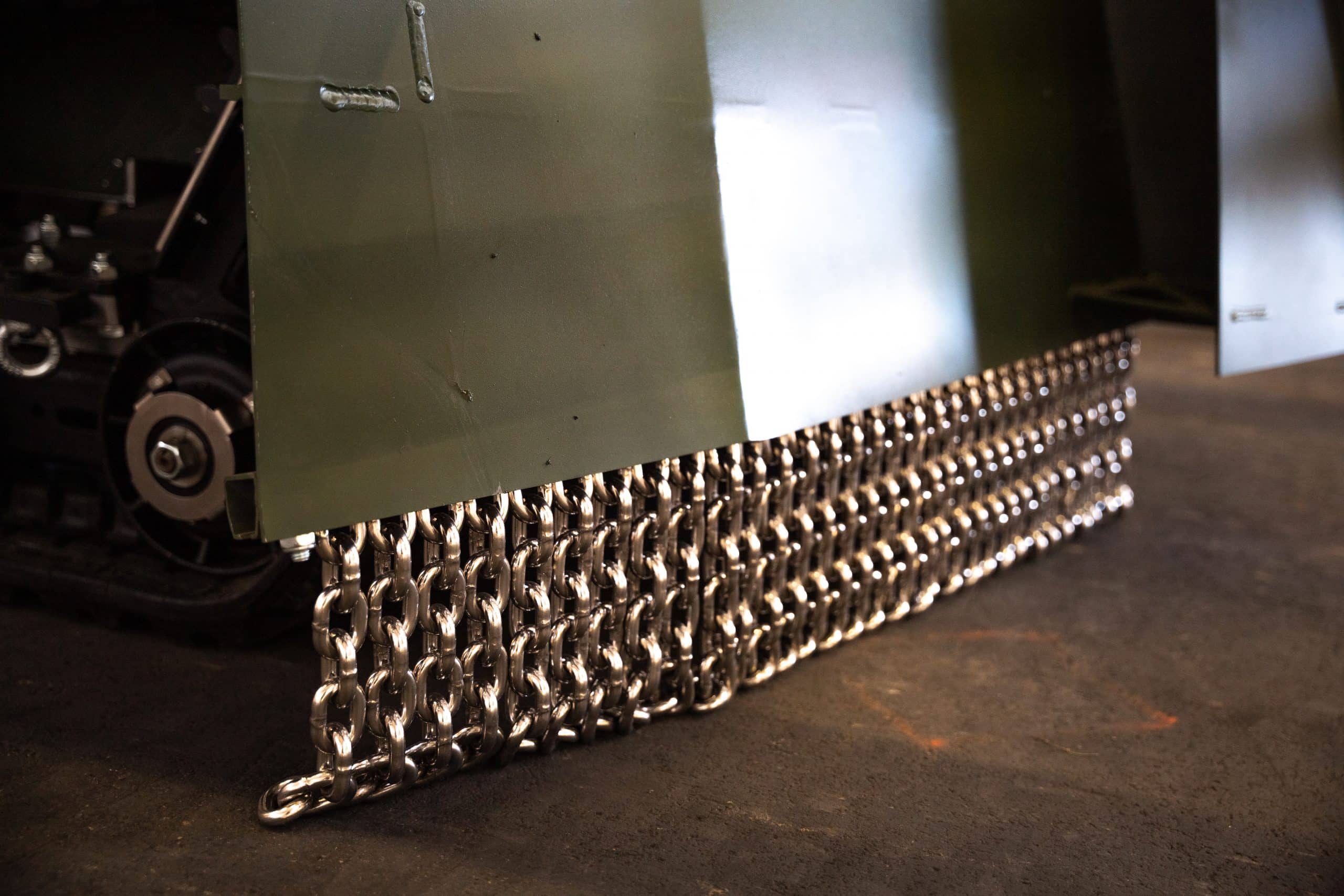

Blast Dispersion Systems

Blast shield and force mitigation suspension allows forces from exploded mines to be dispersed without serious damage to the DeMiner.

Shockwave Resistant Vehicle

Electric powertrain means no combustion engine, no moving parts and no hydraulics - which makes DeMiner resistant to shockwaves from exploded mines.

Low Ground Pressure

Tracked system with all-terrain capability and very low ground pressure assures minimal soil compaction for easier and more efficient follow-up mine clearance.

Operational Superiority

With shockwave-resistant and blast-dispersion vehicle design, the DeMiner offers superior operational efficiency, requiring much less field maintenance.

Easily Transported (B+E license)

The DeMiner can be easily transported via light car-trailer (B+E license) and does not require any additional permits or convoys to go where you need it to be.

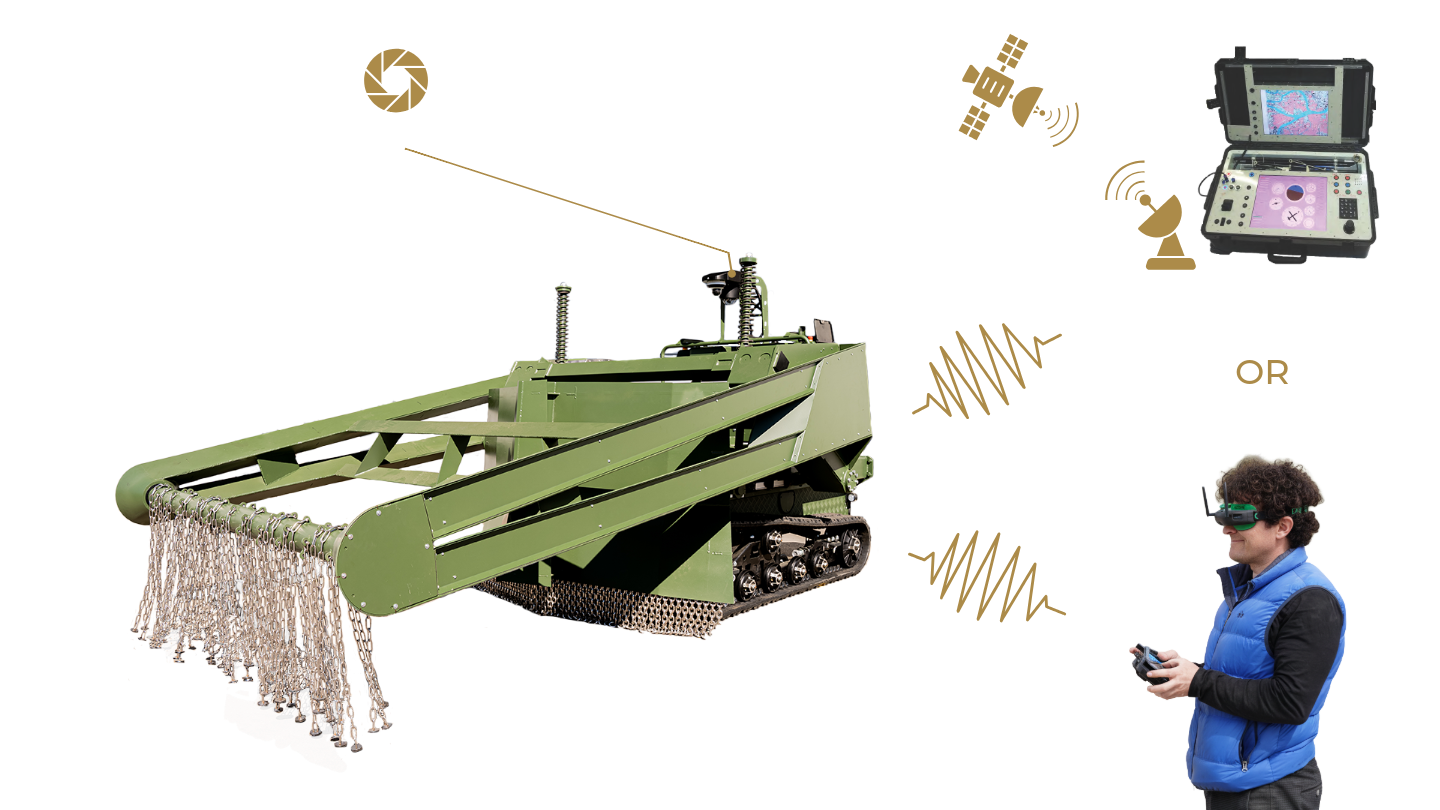

Remote / Autonomous Control

Keep your operators safe and away from danger with intuitive remote control + FPV capabilities and autonomous field operation.

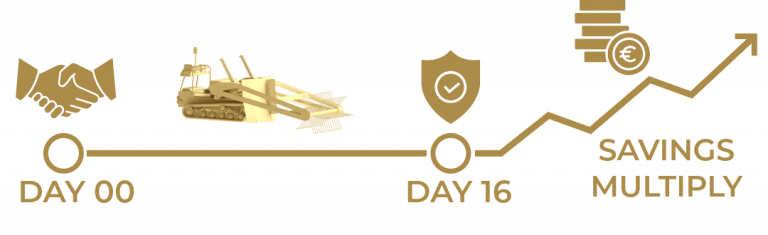

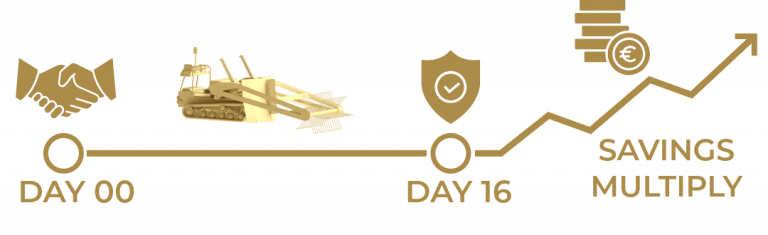

ROI in Just 16 Days

DeMiners low total cost of ownership allows for budget-friendly demining operations and bigger area of certified clearance per project.

Quick Deployment

The DeMiner can begin its operation as soon as it hits the ground, thanks to its plug-and-play system design.

BUILT FOR SAFE DEMINING OPERATIONS

Safe, flexible and reliable CONTROL

DeMiner can be piloted via remote control or command interface, and features autonomous operation. Features multiple operation control options to ensure mission flexibility, redundancy, and ease of use. Also features optional first-person view goggles (FPV) for more precise maneuvering on minefields.

WATCH DEMINER IN ACTION:

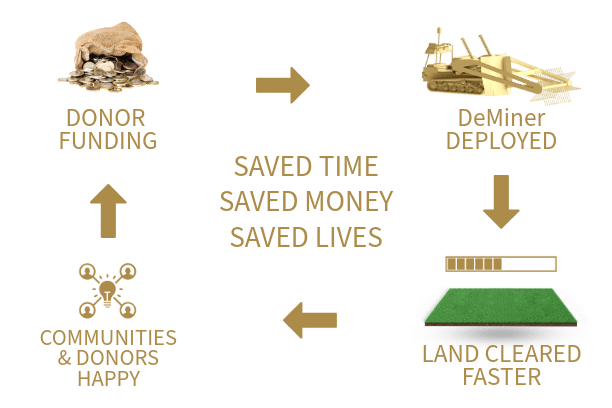

From Donor Funds to Safe GroundS: The ROI of the DeMiner MECHANICAL Clearance System

Landmines remain one of the most destructive legacies of war, blocking land that could be used for farming, housing, and community rebuilding. Every uncleared hectare keeps displaced families from returning home. For UN agencies, NGOs, and humanitarian organizations, the challenge is clear: how to maximize limited donor funding while ensuring safe, efficient mine clearance.

The DeMiner System is built for this exact purpose. This lightweight, electric unmanned ground vehicle (UGV) combines cost efficiency, safety, and practical deployability — delivering a measurable return on investment (ROI) for demining operations worldwide.

The Hidden Costs of Traditional Demining

Manual clearance remains the foundation of demining, but it is slow, dangerous, and labor-intensive. While heavy mechanical clearance systems increase speed, they bring their own challenges:

- High operating costs from diesel fuel and constant maintenance

- Complex logistics, requiring convoys, permits, and specialized transport

- Soil damage and compaction, slowing down manual follow-up teams

- Extended downtime after mine detonations due to costly, complex repairs

The result: Higher costs per cleared square meter, longer timelines, and more risk to deminers.

How the DeMiner System Transforms Mine Clearance

This fully electric, remote-controlled UGV flail demining system, engineered for humanitarian and military mine clearance projects, directly addresses the major pain points of traditional methods:

Lower Operating Costs

Fully electric drivetrain eliminates fuel dependency, cutting running costs and reducing logistical supply chains. Fewer moving parts mean lower maintenance and spare-part expenses.

Blast-Mitigation Technology

An angled blast shield and anti-blast suspension absorb and disperse forces from mine detonations, protecting the vehicle and minimizing repair downtime. NGOs save both money and time by keeping the system operational longer.

Shockwave Resistant Design

Utilizing an electric powertrain gives the DeMiner a unique advantage – it has no combustion engine, moving parts, or hydraulics systems, which makes it highly resistant to shockwaves.

Transport Simplicity

Unlike heavy machinery, the DeMiner is compact and transportable on a standard car trailer (B+E license). No permits, no convoys. Deployment is faster, cheaper, and less bureaucratic.

Zero Time to Action

The plug-and-play design allows the machine to be deployed and start operation as soon as it hits the ground. No lengthy and complex setup required.

Soil-Friendly Clearance

Its low ground pressure tracks minimize soil compaction and avoid accidentally triggering anti-tank mines. This allows faster and safer follow-up by manual clearance teams.

All-Terrain Capability

High-torque electric drive and tracked mobility enable effective operation on slopes, soft soil, and rough terrain — increasing clearance coverage without needing multiple machine types.

ROI That Matters to Donors and NGOs

With our autonomous mechanical mine clearing system, humanitarian organizations and donors can see measurable impact with:

Lower Costs per Square Meter of Cleared Land

With lower operating costs, faster deployment, and reduced downtime, clearance costs are lowered significantly compared to both manual methods and heavy machinery.

Significant Time Saved per Project

Faster mechanical clearance accelerates land release. Communities regain access to their land months earlier, delivering visible impact to donors and beneficiaries.

Improved Safety Outcomes

Every square meter cleared mechanically means fewer human deminers at risk. Fewer injuries translate into direct cost savings on medical care, insurance, and operational delays — and immeasurable humanitarian value.

Every investment translates directly into more land released, more families resettled, and stronger donor accountability.

Clear More Ground - Return on Investment in Just 16 Days

Conventional clearance systems come with enormous daily costs — high fuel consumption, expensive spare parts, and complex transport logistics that quickly add up to hundreds of euros per day in operations alone.

On top of that, their initial purchase price often ranges from several hundred thousand euros to millions and up – plus their lifetime maintenance can rival the cost of the machine itself.

By contrast, the DeMiner’s electric drive, low-maintenance design, and trailer-friendly transport slash daily running costs by up to 70%.

That means your investment can pay itself back in as little as 16 days of operation, while continuing to deliver reliable, budget-friendly clearance long after.

Built for Humanitarian Demining Projects

The DeMiner System is more than just demining equipment. It’s a tool designed around the realities of field operations:

- Fits within tight NGO budgets and donor compliance frameworks

- Crosses borders without the delays of oversized machinery or complex logistics

- Operates reliably with minimal technical support

-

Complements manual clearance teams, speeding up safe certified clearance

From Donor Funds to Safe Grounds

Every euro, pound, or dollar dedicated to mine action carries responsibility. Donors demand efficiency, transparency, and measurable humanitarian impact. The DeMiner System enables NGOs to:

- Clear more land per unit of funding

- Deliver faster, safer results to communities

- Keep their teams protected in the field

That’s the real ROI of the DeMiner: turning donor funds into safe ground, restored livelihoods, and lasting community recovery.

Clear more land, save more lives with DeMiner

The DeMiner is a breakthrough in safe, efficient, and affordable mine clearance equipment. Its lightweight electric design, blast-mitigation technology, and easy trailer transport make it the ideal solution for humanitarian demining projects and post-conflict land release.

From remote villages to agricultural land restoration, this autonomous mechanical mine clearing system empowers NGOs, agencies, and operators to deliver faster clearance, lower costs, and safer outcomes.

Ready to See How DeMiner Can Maximize Your Demining Impact?

Contact us today to discover how this next-generation demining system can help transform donor funds into safe ground and restored communities.

From REMOTE Threats to Secured Grounds: The DefenCe ROI of the DeMiner

In today’s conflicts, adversaries don’t need to be physically present to disrupt advancing forces. With modern rocket and artillery-delivered mines, entire areas can be seeded remotely in a matter of minutes. Temporary logistics hubs, forward supply points, and improvised airfields quickly become high-risk zones, slowing down troop movements and jeopardizing mission success.

These tactics create more than just obstacles — they endanger soldiers, fracture supply lines, and force militaries to choose between speed and safety. Every delay in clearing mined ground risks operational momentum and exposes units to further attacks.

For advancing or retreating forces, the risk is clear: mobility grinds to a halt, supply lines choke, and soldiers are exposed to lethal traps.

Why Traditional Clearance Falls Short

Manual clearance is not a viable option in conflict zones — it is too slow, too dangerous, and exposes soldiers directly to enemy fire. On the other hand, large mechanical systems are faster than manual clearance but bring their own challenges:

-

High operating costs from diesel fuel and constant maintenance.

-

Heavy logistics burden, requiring convoys, permits, and specialized transport.

-

Extended downtime after mine detonations, as repairs are costly and complex.

The DeMiner Advantage in Combat Operations

In modern warfare, where the battlefield is constantly reshaped by remote-mining threats, the DeMiner delivers the decisive edge between halted convoys and uninterrupted momentum. This lightweight, remotely operated, all-electric unmanned ground vehicle (UGV) is built for rapid clearance in contested environments. Its unique design directly addresses battlefield realities:

Lower Operating Costs

Fully electric drivetrain eliminates fuel dependency, cutting running costs and reducing logistical supply chains. Fewer moving parts mean lower maintenance and spare-part expenses.

Blast-Mitigation Technology

An angled blast shield and anti-blast suspension absorb and disperse forces from mine detonations, protecting the vehicle and minimizing repair downtime. This saves both money and time by keeping the system operational longer.

Shockwave Resistant Design

Utilizing an electric powertrain gives the DeMiner a unique advantage – it has no combustion engine, moving parts, or hydraulics systems, which gives it a rugged ‘brick-like’ architecture and makes it highly resistant to shockwaves.

Transport Simplicity

Unlike heavy machinery, the DeMiner is compact and transportable on a standard car trailer (B+E license). It can be forward-deployed by tactical units without convoys or specialized transport. Within minutes, it can be clearing runways, resupply points, or choke points.

Zero Time to Action

The plug-and-play design allows the machine to be deployed and start operation as soon as it hits the ground. No lengthy and complex setup required.

Remote, Safe Operation

Operated via FPV (first-person view) or remote link, clearance is achieved without putting soldiers directly in harm’s way. This enables stand-off operations even under hostile observation or fire.

All-Terrain Mobility

Low ground pressure tracks and a high-torque electric drivetrain allow the DeMiner to traverse mud, rubble, slopes, and uneven ground — essential for clearance in improvised or disrupted environments.

Tactical Payoff: Keeping the Force Moving

The DeMiner system was built for exactly this tactical payoff. Compact, mobile, and fully remote-operated, it can be deployed within minutes to clear hazardous zones without putting personnel at risk. Whether securing a newly established airstrip, reopening a mined route, or restoring access to logistics hubs, the DeMiner ensures you can:

Secure supply hubs and forward airstrips against remote-mining attacks.

Accelerate maneuver operations by clearing paths and routes quickly.

Protect soldiers by reducing direct human exposure to minefields.

Preserve tempo and initiative by denying your adversaries the ability to stall or attrit advancing units.

The Defense ROI of Demining

In military operations, ROI is measured in lives saved, time gained, and momentum preserved. Every hour a logistics hub is down is an hour of vulnerability. Every minefield that halts resupply exposes soldiers to greater risk.

By integrating an autonomous demining capability, commanders can maintain operational tempo, protect logistics lifelines, and deny adversaries the advantage of remote mining. With its low-cost operation, rapid deployability, and blast-resilient design, the DeMiner ensures that forces stay supplied, mobile, and safe.

Keep Your Momentum Going - Return on Investment in Just 16 Days

Conventional clearance systems come with enormous daily costs — high fuel consumption, expensive spare parts, and complex transport logistics that quickly add up to hundreds or thousands of euros per day in operations alone. On top of that, their initial purchase price often ranges from several hundred thousand euros to millions and up – plus their lifetime maintenance can rival the cost of the machine itself.

By contrast, the DeMiner’s low purchase price, electric drive, low-maintenance design, and trailer-friendly transport lower total cost of ownership and slash daily running costs by up to 70%. That means your investment can pay itself back in as little as 16 days of operation, while continuing to deliver reliable, budget-friendly clearance long after.

Built for Modern Combat Operations

The DeMiner System is more than just demining equipment — it’s a tactical asset designed for the realities of active defense operations:

- Deploys rapidly to forward positions, temporary logistics hubs, and improvised airfields

- Operates reliably in contested environments with minimal technical support

- Compact and mobile, avoiding the delays and vulnerabilities of oversized machinery

It complements military engineering units, accelerating the clearance of hazardous areas and keeping soldiers out of danger, ensuring operational momentum is maintained.

From Mission Funding to Operational Readiness

Every resource allocated to defense operations carries strategic responsibility. Commanders demand solutions that protect personnel, maintain mobility, and deliver measurable results. The DeMiner System enables armed forces to:

-

Clear mined zones faster, keeping supply lines and forward positions operational

-

Reduce risk to soldiers during advance, retreat, or resupply missions

-

Preserve mission tempo and tactical advantage in dynamic combat environments

That’s the real ROI of the DeMiner: turning mission resources into secure ground, uninterrupted operations, and safer forces.

Clear Hazardous Zones, Protect Your Forces with DeMiner

The DeMiner is a breakthrough in rapid, safe, and reliable mine clearance for modern combat operations. Its lightweight electric design, blast-mitigation technology, and easy trailer transport make it ideal for forward deployment and high-risk zones.

From forward supply points to temporary airfields and contested routes, this autonomous mechanical mine-clearing system empowers military engineering units to maintain operational momentum, reduce casualties, and secure critical terrain faster than conventional methods.

See How DeMiner Enhances Your Operational Capability

Contact us today to discover how this next-generation demining system can keep your troops safe, maintain supply lines, and turn hazardous zones into secure, operational ground.

MEDIA GALLERY

DEMINER IMAGE COLLECTION:

Create Your Own Custom EV Solution

Your Mission - Our Technology

Pek Automotive has an extensive technological foundation that it has been developing for over 25 years (since 1998), used for custom EV development in a wide variety of sectors.

These technologies are ideal to quickly develop and upgrade autonomous electric vehicles in agriculture, civil protection, defence & rescue, space, and more.

If you’re interested in our technologies or already have a project in mind, please feel free to contact us about getting a license for commercial or private use.

Contact Us

If you have any questions or need any additional information, please do not hesitate to contact us via the form below and we will get back to you as soon as possible.

MAIN TECHNOLOGIES

EV 48 POWER DRIVETRAIN

The world’s first ready-to-use 48V on-board electric drivetrain kit for fast design and manufacturing of various manned and unmanned ground vehicle platforms.

The IntEn controller provides high torque with a low-voltage Permanent Magnet Synchronous Motor (PMSM) at zero RPM.

To learn more about EV48 Power Drivetrain please visit our official website by clicking the button below.

R-WAVE 2D MP RADAR

A compact, high-precision radar sensor for autonomous systems.

Detects objects, measures distances, and tracks speeds reliably in all weather, even in dust, fog, or low visibility.

Durable and low-maintenance, it ensures safe and accurate navigation.

To learn more about R-Wave 2D MP Radar please visit our official website by clicking the button below.

R-WAVE RTK

A Real-Time Kinematic positioning system for various UGV applications. Significantly enhances the accuracy of GNSS (Global Navigation Satellite System) positioning.

Fast installation, fast mapping, and positioning 10 mm within the range of a few kilometers.

To learn more about R-Wave RTK please visit our official website by clicking the button below.

R-WAVE RPOWER

LiFePO4 power unit with BMS and charging station.

Enables endless configuration options for the development of custom special-purpose electric vehicles.

Embedded BMS, high-current buses, modular design.

To learn more about R-Wave Rpower please visit our official website by clicking the button below.

TEROAIR

An application system that links field vehicles and customers to provide real-time data reports for mission tracking.

It combines numerous features into a single piece of software, making on-board module installation simple.

To learn more about TeroAir App please click the button below.

R-WAVE WEATHER STATION

UGV on-board weather station for mission action optimization.

One computer integrates all of the devices and sends data to the main server.

To learn more about R-Wave Weather Station please visit our official website by clicking the button below.

R-WAVE AUTONOMOUS

Full autonomous navigation for robots & electric vehicles. Build precise area maps using radar, RTK, GNSS and reflectors, then let the vehicle run independently using only the map and obstacle detection.

Ideal for orchards, vineyards, and repetitive tasks—working without constant GNSS or internet.

To learn more about R-Wave Autonomous please visit our official website by clicking the button below.